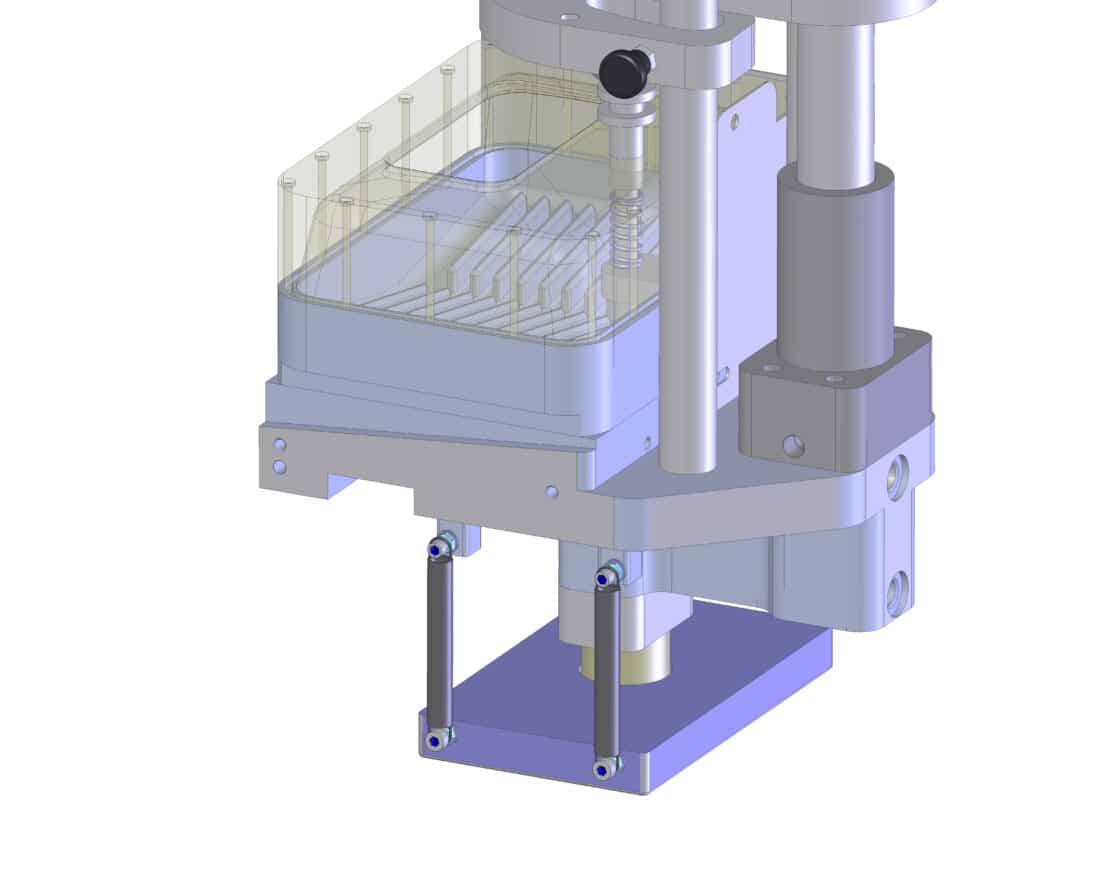

Semi-automatic wood filling system, with exchange tank and cooling unit.

For the processing of Novoryt-Forte granules in solid wood

and veneer, as well as in lightweight construction.

- Machining width 0 - 700 or 0 - 1000 mm and a height of 150mm

- Possible sliding surfaces: roller conveyor, plastic guides (for furniture parts), sliding brushes (for fragile surfaces) or 2-D rolls.

- Hole detection by eye, alignment is done by hand, using the crosshairs

- The filling process is started by using a foot pedal

- Connecting ports: 16 Amps euro plug, 400 Volts and a compressed air connection

- Tank capacity: 1,8 litres

- Melting capacity: sufficient for continuous use

Advantages compared to the existing systems:

- Continuously melting a small amount of granules. This continuous

process prevents particles from settling and therefore there's no need to stir the melded substance

and therefore the weaning of floating particles is prevented. - The melting tank is easily replaced,

which makes it easy and quick to change colours. - There is no pressure on the system when it's at rest.

- A volume injection is possible

- Surfaces with a width up to 1,000 mm can be filled.

- The system is suitable for veneered parts.

- It's possible to fixate knots in raw floorboards.

With this systems knots, cracks and other defects can be filled in a quick and easy way. When applying volume, this system is also suitable for anchoring fittings in lightweight panels, used for furniture construction. And last but not least, this system is suitable for robot- and CNC machines.